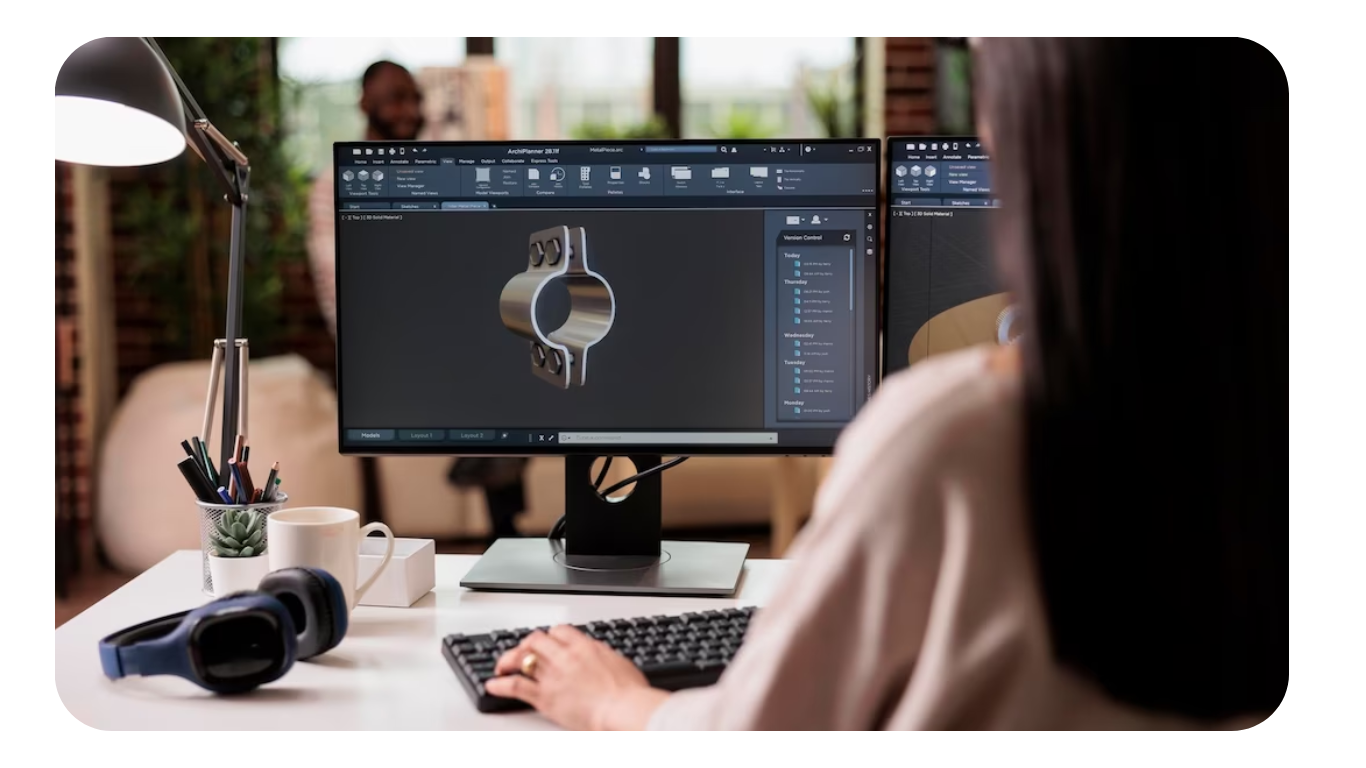

Engineers, construction site managers, and architects often use computer-aided design (CAD) to assist them in their projects. CAD is a method of creating designs in 2D and 3D simulations, which originated in the 1960s. It became more accessible in the 1990s with the introduction of tools like CATIA and AutoCAD. CAD is commonly used by professionals such as engineers, architects, and construction workers.

WHAT IS COMPUTER-AIDED DESIGN (CAD)?

CAD allows experts to create accurate design representations and has replaced manual design drafting. It enables engineers to develop, modify, and optimize designs digitally. CAD software also calculates how different materials interact, which is important for contractors who add specifications to the project.

CAD programs have many features and have become essential in the construction, architecture, and engineering sectors. Its advancement has transformed these industries and the processes involved in complex projects.

HOW IS CAD IMPLEMENTED?

CAD is implemented in electronic forms for printing, machining, and manufacturing. It is integrated into various stages of a design’s lifecycle in different professions:

- Architecture: Architects use CAD extensively, especially in complex project design. Building information modeling (BIM) software like Revit is commonly used by larger firms, while smaller companies may utilize a combination of tools.

- Product Design: Industrial designers employ CAD programs such as Fusion 360, Inventor, or SolidWorks to visualize components and predict their functionality.

- Graphic Design: Graphic designers utilize 2D or 3D CAD software to create visual mockups. Graphic CAD software allows them to experiment with effects, typography, shapes, and backgrounds for artwork.

- Engineering: Engineers use CAD for a wide range of purposes, including drafting buildings, infrastructure components, circuits, telecommunication networks, mechanical items, medical devices, utilities, and manufacturing parts.

INCREASES PRODUCTIVITY

CAD software increases productivity by enabling developers to work faster, reduce production costs, and complete projects more efficiently. It eliminates the need for manual sketches and designs, allowing designers to experiment and save drafts digitally. Smaller teams can be maintained, resulting in affordable products, accelerated production, and flexible product improvement.

REDUCES ERRORS

CAD helps prevent mistakes in the following ways:

- It prevents human error significantly when professionals use CAD. If someone inputs erroneous parameters, the software alerts them to these mistakes.

- After designing a product using CAD software, the user can directly transfer the computer model to manufacturing equipment. Since errors were averted during the development of the component, the machinery can seamlessly craft the item, avoiding resource waste.

- CAD eliminates the need for physical prototyping, which was a time-consuming process in manual design. Instead, designers can simulate all necessary testing virtually in the program, enabling quick prototyping.

- Adjustments are often required during production. Implementing manual changes typically results in some human error, as each product variable requires independent input. With CAD, engineers can simultaneously change various views corresponding to the first alteration, making alterations easier.