This article describes the various types of underground cables used for power transmission from the generating station to the distribution substation. Unlike overhead transmission lines, underground cables are laid below the ground surface in areas where using overhead lines is impractical, difficult, or dangerous. These cables are commonly employed in densely populated areas, and although their initial cost is higher compared to overhead transmission lines of similar capacity, they offer numerous advantages.

Types of Underground Cables Based on Voltage Rating

The classification of underground cables is determined by the system voltage at which they operate. The voltage rating is a crucial factor that influences the level of insulation, current carrying capacity, and impedance of the cables. Here are the different types based on voltage rating:

Low-voltage cables: These cables operate at voltages up to 1kV.

High-voltage cables: Designed for operating voltages up to 11kV.

Super tension cables: Capable of handling operating voltages up to 33kV.

Extra High tension cables: Designed for operating voltages up to 66kV.

Extra super voltage cables: Used for operating voltages beyond 132kV.

Higher voltage cables are preferred for power transmission as they allow stepping up the generated voltage to reduce current and efficiently transmit power. Higher voltage levels result in thinner cables, reducing weight, installation costs, and impedance.

Types of Underground Cables Based on Number of Conductors

The classification of underground cables based on the number of conductors considers factors such as the intended load, voltage drop, continuous current rating, and earth fault loop impedance. Here are some common types:

3-Core Cables: These cables are used for perfectly balanced three-phase systems where the three-phase currents are equal in magnitude and have a 120-degree phase angle. No neutral conductor is required since the three-phase loads are identical.

3.5-Core Cables: These cables have a neutral conductor and are used at higher voltages. They can handle out-of-balance currents in systems with non-identical loads, where the neutral conductor carries the imbalance current.

4 Core Cables: These cables are used in systems with high out-of-balance currents and non-linear loads. The neutral conductor in these cables has the same thickness as the main conductor since it carries a significant amount of current.

5 and 6-Core Cables: These cables are employed in systems where the out-of-balance or neutral current is larger than the phase currents. Underground cables typically use 3 or 4 core configurations.

Types of Underground Cables Based on Insulation

Insulation plays a crucial role in underground cables as it ensures the safety of internal conductors from external factors and facilitates safe handling. Different insulating materials, such as paper, rubber, PVC, and cross-linked polyethylene, are utilized based on their dielectric strength. Here are some common insulating materials and their dielectric strengths:

- PVC: 200kV/cm

- Mica: 118MV/m

- Teflon: 60MV/m

- Glass: 14MV/m

- Rubber: 12MV/m

- Impregnated paper: 30kV/mm

- Silicon insulator: 20MV/m

- HDPE Insulator: 20MV/m

- Nylon: 14MV/m

- Porcelain insulator: 12MV/m

- Air: 3MV/m

- Vacuum: 30MV/m

Actual ratings may vary depending on operating conditions.

Types of Underground Cables Based on Construction

Underground cables can be classified based on their construction methods. Here are some common types:

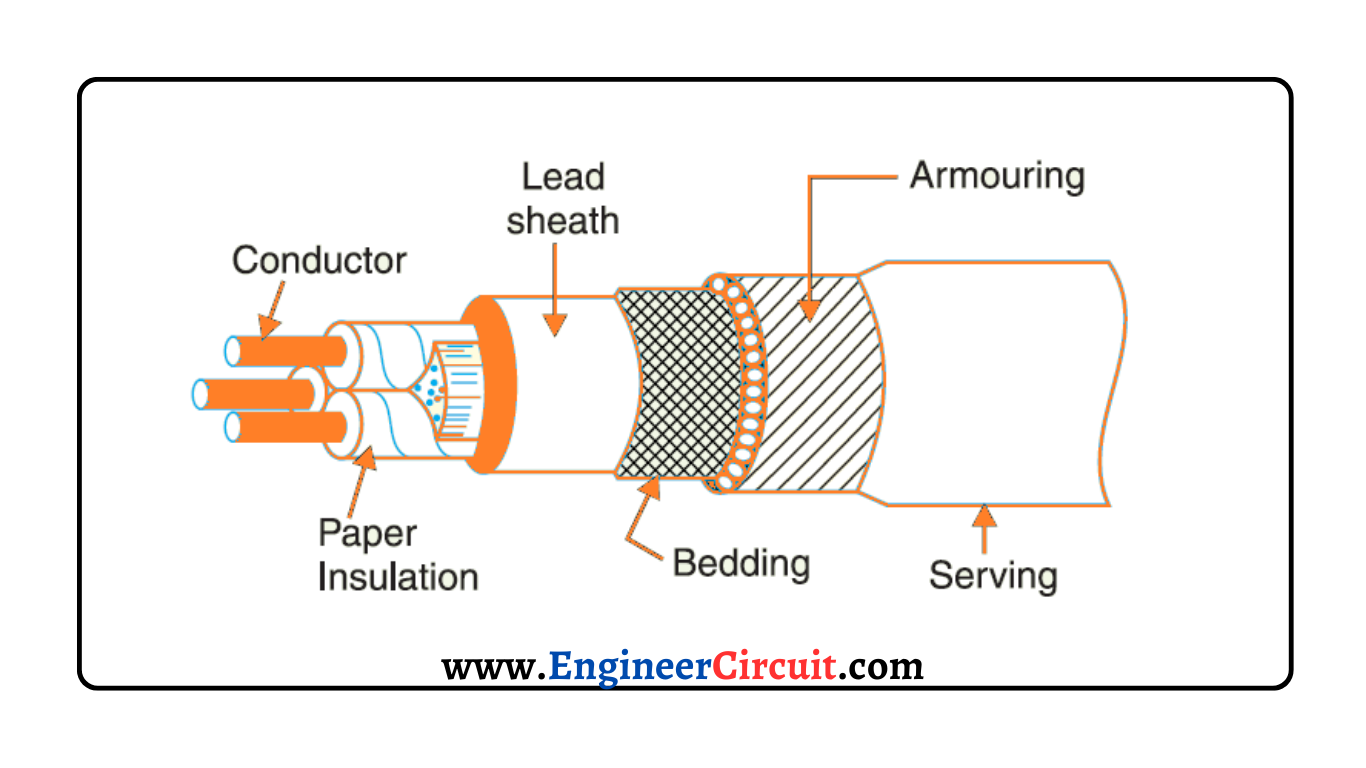

Belted Cables: These cables consist of three conductors bundled together and held by a paper belt. Each conductor is insulated with impregnated paper, and the gaps between conductors and the insulating belt are filled with flexible material like jute. A metallic sheath and armor protect the cables.

Screened Cables: Screened cables come in two types: H-type and S.L. type.

H-Type: Individual conductors are insulated with paper and covered with a metallic cover. Metallic tape groups the covered conductors together, and a lead sheath and copper tape are grounded.

S.L. Type: Similar to H-type cables, but each conductor has an individual lead sheath instead of an overall sheath, providing greater flexibility and minimizing conductor-to-conductor breakdown faults.

H.S.L Type: These cables combine H and S.L. types, with each core insulated using impregnated paper and provided with separate lead sheaths.

Pressure Cables: Used for system voltages exceeding 66kV, pressure cables filled with oil or gas are employed to improve dielectric strength and prevent insulation failure.

Oil-Filled Cables: Oil is filled through the cable under suitable pressure, utilizing the same oil used for impregnating paper insulators.

Gas-Filled Cables: Pressurized gas, usually nitrogen, circulates around the cable in a steel pipe. These cables are used in high-voltage transmission and endure high-load currents.

Types of Underground Cables Based on Installation

Underground cables can also be classified based on their installation methods. Here are some common installation types:

Directly buried installation: The cable is laid directly in a trench without any additional elements. A cooling pipe may be included if necessary.

Tunnel installation: Tunnels are dug to allow the cable to cross under rivers or other obstacles. Although installation and maintenance costs are higher, this method provides additional protection.

Trough installation: Concrete troughs are dug, and the cable is laid within them. This installation type offers easy access and maintenance as the cables are visible above the ground.

Gas-insulated line installation: For high-voltage power lines, gas insulation is used during installation to enhance operational safety. This technique is relatively new and incurs higher initial costs.

Understanding the different types of underground cables helps ensure the appropriate selection and deployment for various power transmission needs.