Construction of A Two-Stroke Engine

During only one crankshaft revolution, a two-stroke engine completes a power cycle with two strokes of the piston.

History

A Scottish engineer named Dugald Clerk created the design for a commercial two-stroke engine involving in-cylinder compression in 1881.

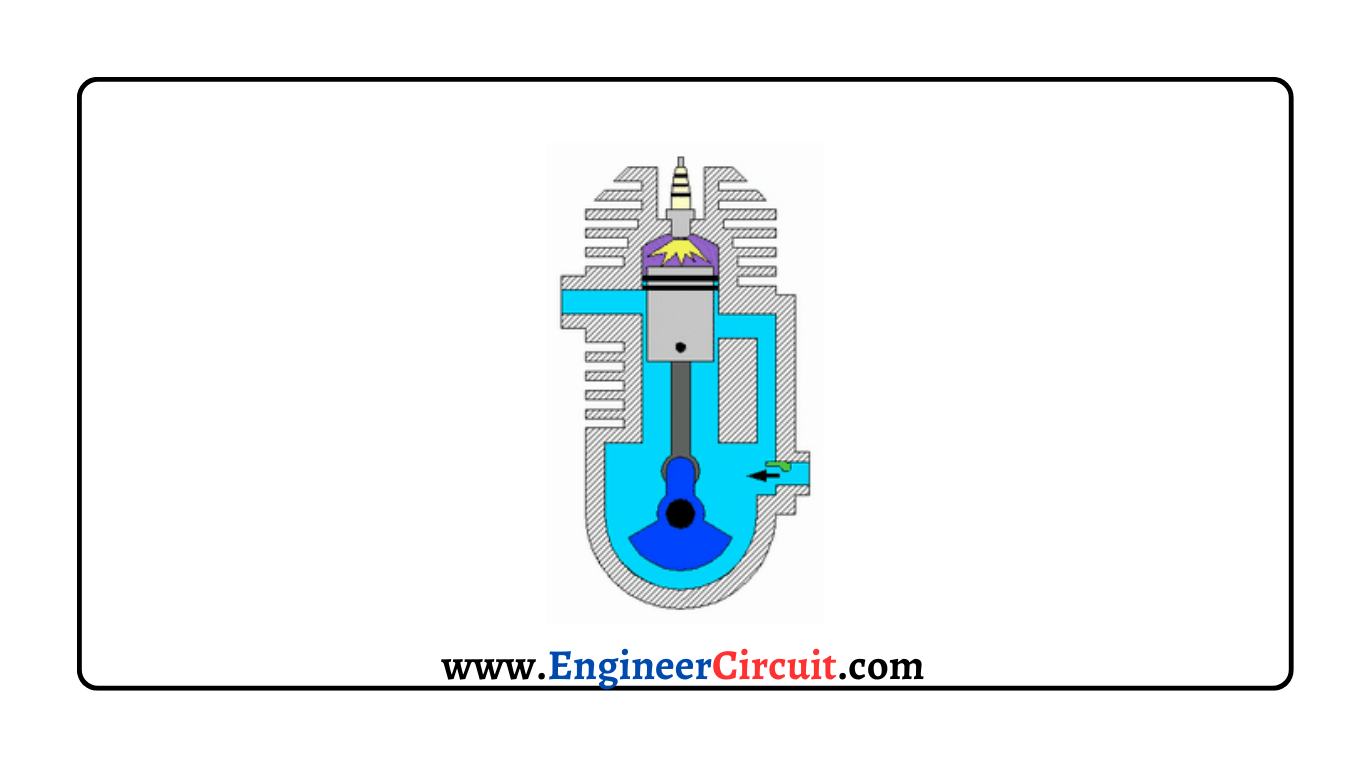

Construction of a Two-Stroke Engine

The construction of a two-stroke engine involves the following components:

- Piston: Transfers the expanding forces of gases to the mechanical rotation of the crankshaft via a connecting rod.

- Crankshaft: Allows the conversion of reciprocating motion to rotational motion.

- Connecting rod: Transfers the motion of the piston to the crankshaft.

- Flywheel: A mechanical device used to store energy.

- Spark plug: Enables the expansion of gases by delivering electric current to the combustion chamber and igniting the air-fuel mixture.

- Counterweight: Reduces vibrations caused by imbalances in the rotating assembly.

- Inlets and outlets: Allow the entry and exit of fresh air into the cylinder.

Working of Two-Stroke Engine

The working of a two-stroke engine primarily consists of two halves: the up-stroke and the down-stroke. During the up-stroke, the piston is pushed from Bottom Dead Center (BDC) to Top Dead Center (TDC), compressing the fuel-air mixture. The spark plug ignites the mixture, causing it to expand and push the piston down. This opens the inlet port, allowing the mixture to be sucked inside the crankcase.

When the mixture is pushed up into the combustion chamber during the previous upstroke, a partial vacuum is created. During the down-stroke, the mixture enters the combustion chamber as the piston moves from TDC to BDC. Fresh air enters the combustion chamber and mixes with the fuel. It is worth noting that in this stroke, the crankshaft makes a 180° rotation.

Types of Two-Stroke Engine

There are different types of two-stroke engines, including:

- Piston-Controlled Inlet Port: Simplest and most common design.

- Reed Inlet Valve: Simple but highly effective check valve.

- Rotary Inlet Valve: Uses a rotating member to open and close the intake pathway.

- Cross-Inlet Scavenging: Transfer and exhaust ports are on opposite sides of the cylinder, and a deflector on top of the piston directs the fresh intake charge into the upper part of the cylinder.

- Loop Scavenging: Uses carefully shaped and positioned transfer ports to direct the flow of fresh mixture toward the combustion chamber as it enters the cylinder.

- Uni-flow Scavenging: Charge air enters at one end of the cylinder controlled by the piston, while the exhaust exits at the other end.

- Stepped Piston Engine: Top-hat-shaped engine with the upper sections forming the regular cylinder and the lower section performing a scavenging function.

Applications

Two-stroke engines are less expensive to build and find application in chainsaws, weed-eaters, off-road motorcycles, and racing vehicles.

FAQs:

What are petrol and diesel engines?

A petrol engine uses petrol as fuel, where air and petrol are mixed in the carburetor before being passed into the cylinder. Petrol engines rely on spark plugs to ignite the mixture. A diesel engine uses diesel as fuel and relies heavily on compressed air. Diesel engines are cheaper and more efficient compared to petrol engines.

What is the difference between a two-stroke and four-stroke engine?

In a two-stroke engine, the entire combustion cycle takes place within a single piston stroke, whereas in a four-stroke engine, the piston completes two full strokes. Four-stroke engines are more efficient because fuel is consumed only once every four strokes. Additionally, four-stroke engines are quieter compared to the high-pitched buzzing sound of two-stroke engines.